Products

Industries

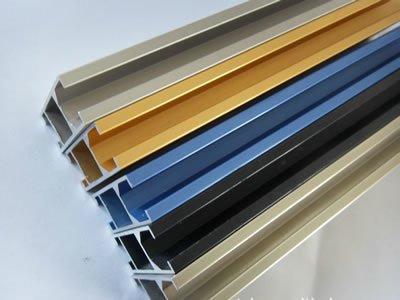

Anodizing power supply is mainly used in large stainless steel, aluminum oxidation, aluminum alloy oxidation, anodic anodizing, hard anodizing, porcelain oxidation, micro arc oxidation and so on.

High frequency anodizing power supply usually has precise constant-current and constant-voltage output characteristics, and the control accuracy is within ±0.5V and ±0.5A, respectively.

Support local and remote control two modes of operation. It has the function of timing and timing of oxidation process. Optional step voltage, current, time control output, full digital control, and perfect equipment protection function, with phase loss, short circuit, over current, over voltage, etc.

The use of aluminum anodizing rectifiers can reduce the porosity, the formation rate of crystal nuclei is greater than the growth rate, promote the refining of crystal nuclei, improve the binding force, make the passivation film breakdown, is conducive to the solid bonding between the substrate and the coating, reduce the internal stress of the coating, improve the lattice defects, impurities, holes, nodules, etc., easy to get the coating without cracks, reduce additives, It is beneficial to obtain stable alloy coating. Improve the dissolution of anode, improve the mechanical and physical properties of coating, such as increasing density, reducing surface resistance and body resistance, improving toughness, wear resistance, corrosion resistance, and can control the hardness of coating.