Products

Industries

Surface treatment rectifiers are DC power supply devices specifically designed for processes such as electroplating, electrolysis, and anodizing. Their performance directly determines the coating quality, energy consumption level, and production efficiency. With the advancement of intelligent manufacturing, these devices are evolving from simple power converters into key nodes for process intelligence.

Surface treatment rectifiers convert industrial frequency AC power into smooth DC power through a three-phase bridge rectifier circuit. The core technology lies in precisely controlling the ripple coefficient of the output voltage and current. High-quality rectifiers can control ripple to within 5%, ensuring uniform deposition of metal ions on the workpiece surface. Compared to ordinary industrial power supplies, their unique features include:

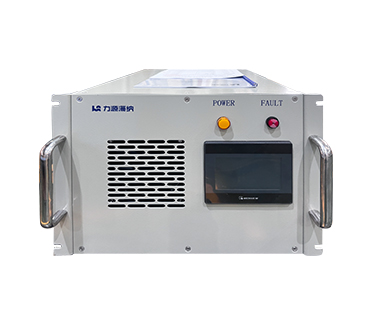

IGBT Type Electroplating Rectifier

https://www.ly-rectifier.com/pro_cat/new-generation-synchronous-energy-saving-power-supply/

Pulse Power Supply

https://www.ly-rectifier.com/app_cat/pcb-eletroplate/

Anodizing Rectifier

https://www.ly-rectifier.com/app_cat/aluminum-anodizingcoloring/

High Power SCR Rectifier System

https://www.ly-rectifier.com/pro_cat/silicon-controlled-rectifier/

The technological evolution of surface-treated rectifiers reflects the profound transformation of the manufacturing industry from "experience-driven" to "data-driven." Choosing the right rectifier is not only an equipment procurement decision, but also a strategic investment to enhance product added value and achieve green manufacturing.