Products

Industries

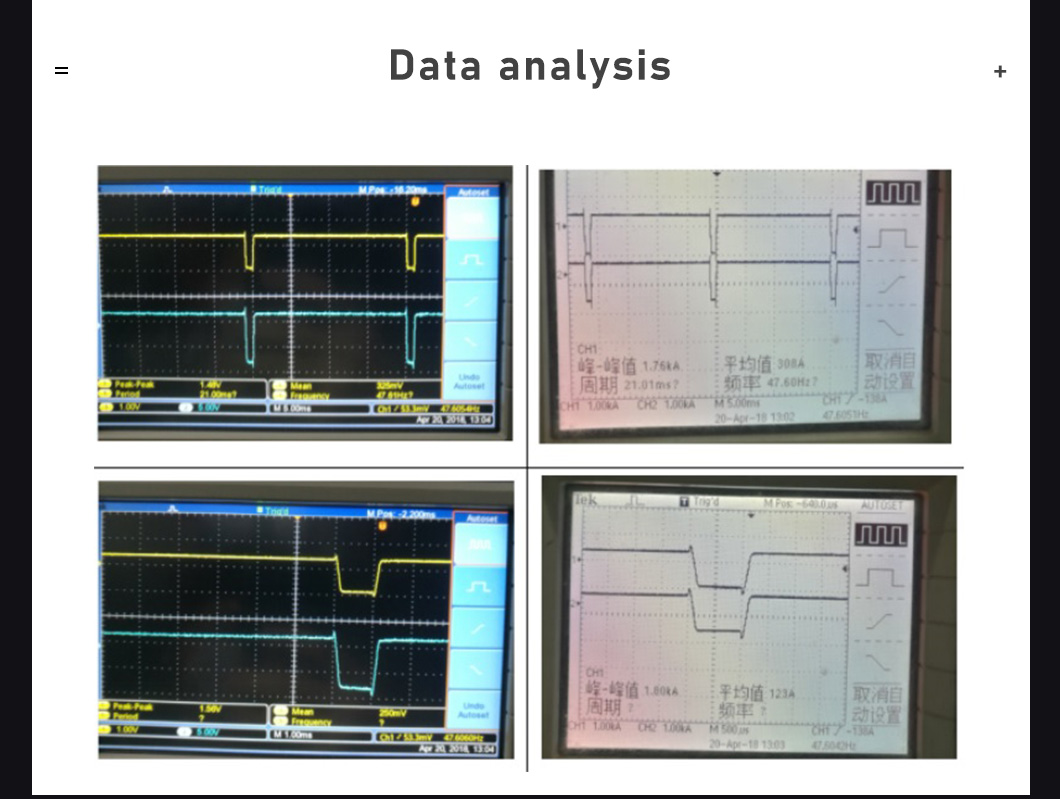

Input parameters: Three phase AC380V/440V±10%, 50-60HZ

Output parameters: 0~150V 0~20KA

Output mode: Common DC output

Cooling method: Air cooling, water cooled or oil cooled

Power supply type: IGBT-based

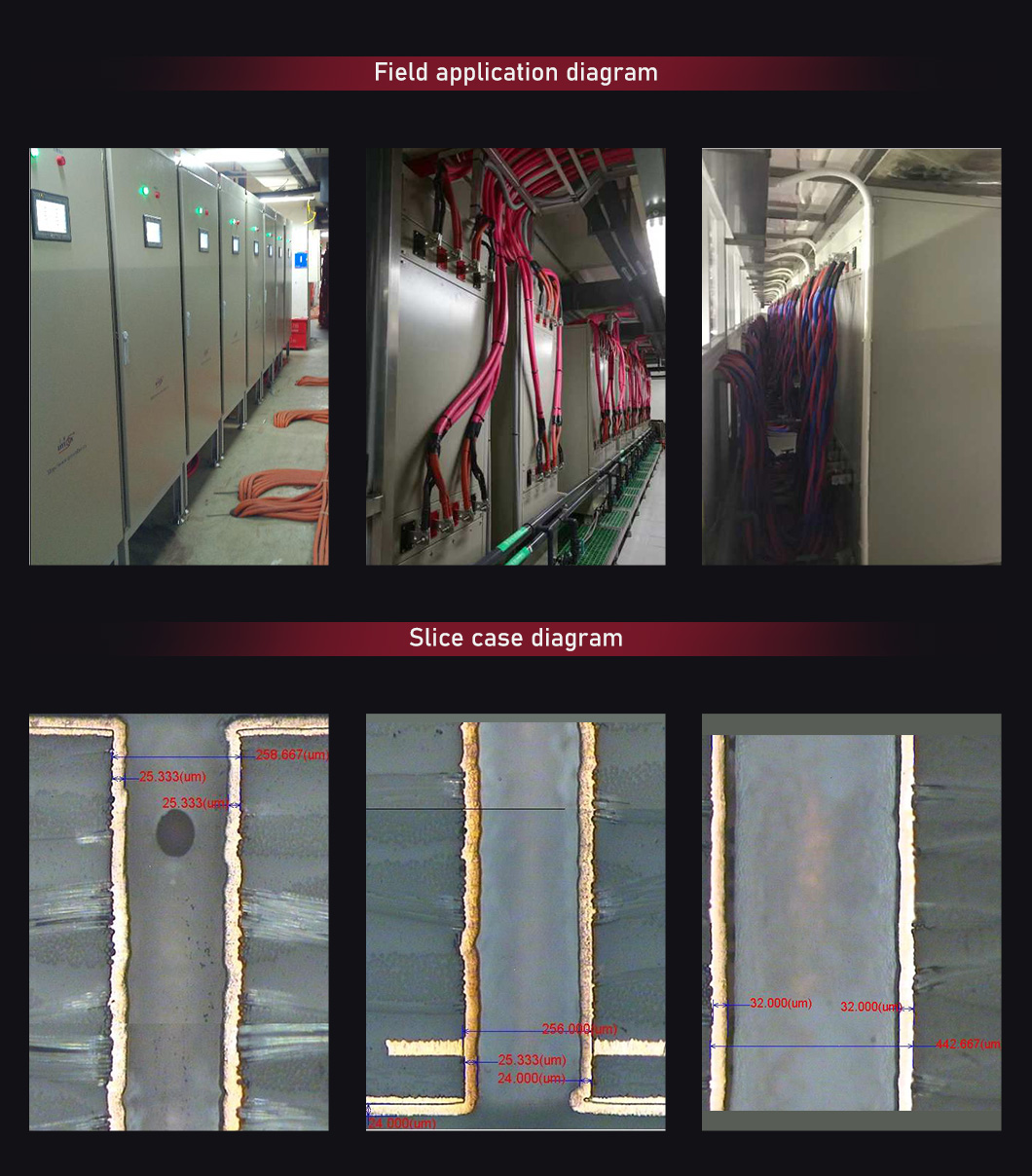

Application Industry: aluminum alloy hard oxidation, hard anodizing and thick film oxidation.

Anodic oxidation is accomplished by immersing aluminum in an acidic electrolyte and running an electric current through the medium. The cathode is installed inside the anodic oxidation tank. Aluminum acts as an anode, so oxygen ions are released from the electrolyte and combine with the aluminum atoms on the surface of the anodized part. Therefore, anodic oxidation is a highly controlled oxidation problem – an enhancement of natural phenomena. Anodic oxidation is generally used to strengthen the product hardness, corrosion resistance and do surface treatment. One of the materials required to make a set of anodic oxidation equipment in addition to the anode tank, including the anode cathode, refrigerator, etc., rectifier is essential.

Anodic oxidation, electrochemical oxidation of metals or alloys. Aluminum and its alloy in the corresponding electrolyte and specific process conditions, due to the action of impressed current, aluminum products (anode) on the formation of a layer of oxide film process. Anodizing, unless otherwise specified, usually means anodizing sulfuric acid.

Aluminum’s inherent softness and susceptibility to surface damage pose significant challenges across engineering applications. These limitations demand surface enhancement solutions to boost durability while maintaining the metal’s advantageous properties. Among available technologies, anodizing emerges as the dominant industrial approach – a transformative electrochemical technique developed through decades of refinement.

This controlled oxidation process builds protective ceramic layers directly from the base metal. Engineers leverage these synthetic oxide structures to achieve combinations of corrosion resistance, architectural aesthetics, dielectric properties, and tribological performance unattainable with raw aluminum substrates.

| Input voltage | Three phase AC380V/440V±10%, 50-60HZ |

| Voltage regulation precision | ≤1% |

| Current regulation precision | ≤1% |

| Rated efficiency | ≥85% |

| Operation environment | -10-40℃ |

| Storage temperature | -20-50℃ |

| Cooled mode | Air cooling, water cooled or oil cooled |

| Operation conditions | 24-hour operation under full load |

| On time | 1 – 1000MS |

| Off time | 1 – 1000MS |

| Stability precision | ≤1% |

| Output wave form | DC, single pulse, DC overlapping pulse, double-pulse, etc. |

| Rated efficiency | ≥85% |

| Operation environment | -10-40℃ |

| Storage temperature | -20-50℃ |

| Cooled mode | Air cooling, water cooled or oil cooled |

| Operation conditions | 24-hour operation under full load (under 1500m) |

| Output voltage | 0-150V |

| Output current | 0-20000A |

| *OK to customize as per requirements* | |

If you need other power anodizing rectifier, we can custom design them according to customer requirements. Please contact us.

Seeking 0~150V 0~20KA pulse rectifier for hard anodizing? Liyuan Haina Rectifier, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Canada, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.

Hot Tags: 0~150V 0~20KA Pulse Rectifier for Hard Anodizing, Pulse Power Supply, Anodizing rectifier, Surface Treatment, hard anodizing, Air cooling, water cooled, industrial rectifiers

If you have more questions, please leave us a message and we will contact you within 24 hours.