Products

Industries

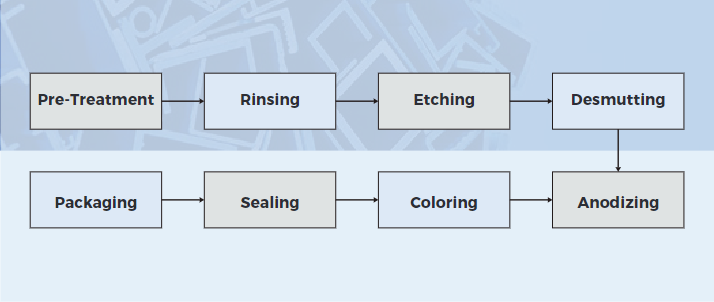

Pre-Treatment:

Cleaning is done in a non-etching, alkaline detergent heated to approximately 145 degrees Fahrenheit. This process removes

Rinsing:

Multiple rinses, some using strictly de-ionized water, follow each process step.

Etching (chemical Milling):

Etching in caustic soda (sodium hydroxide) prepares the aluminum for anodizing by chemically removing a thin layer of aluminum.This alkaline bath gives the aluminum surface a matte appearance.

Desmutting:

Rinsing in an acidic solution removes unwanted surface alloy constituent particles not removed by the etching process

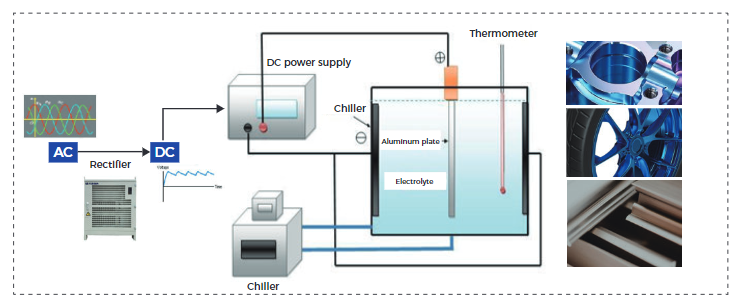

Anodizing:

Aluminum is immersed in a tank containing an electrolyte having a 15% sulfuric acid concentration. Electric current is passed through the electrolyte and the aluminum is made the anode in this electrolytic cell; the tank is the cathode. Voltage applied across the anode and cathode causes negatively charged anions to migrate to the anode where the oxygen in the anions combines with the aluminum to form aluminum oxide (AI2O3).

Coloring:

Anodic films are well suited to a variety of coloring methods including absorptive dyeing, both organic and inorganic dyestuffs, and electrolytic coloring.

Sealing:

In all the anodizing process, the proper sealing of the porous oxide coating is absolutely essential to the satisfactory performance of the coating.

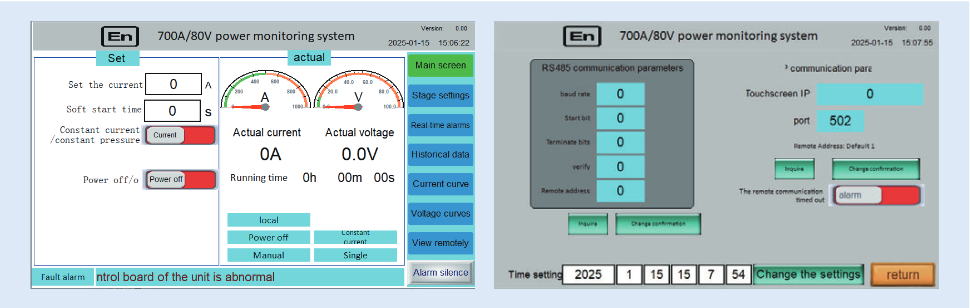

Accurate control of process parameters

High frequency anodizing power supply usually has precise constant-current and constant-voltage output characteristics, and the control accuracy is within ±0.5V and ±0.5A, respective.

Support local and remote control two modes of operation

The use of aluminum anodizing rectifiers can reduce the porosity,the formation rate of crystal nuclei is greater than the growth rate. promote the refining of crystal nuclei, improve the binding force, make the passivation film breakdown,is conducive to the solid bonding between the substrate and the coating, reduce the internal stress of the coating, improve the lattice defects, impurities, holes, nodules, etc. easy to get the coating without cracks, reduce additives, lt is beneficial to obtain stable alloy coating.

Advantages of rectifiers in anodizing

Support local and remote control two modes of operation. lt has the function of timing and timing of oxidation process. Optional step voltage, current, time control output, full digital control, and perfect equipment protection function, with phase loss, short circuit, over current, over voltage, etc.

Improve the dissolution of anode

Improve the dissolution of anode,improve the mechanical and physical properties of coating, such as increasing density, reducing surface resistance and body resistance, improving toughness, wear resistance, corrosion resistance, and can control the hardness of coating