Products

Industries

Input parameters: Three phase, AC380V±10% ,50~60HZ

Output parameters: AC : 0~250V 0~4KA

Output mode: Common DC output

Cooling method: Water cooling

Power supply type: Silicon controlled rectifier

Application Industry: Metal materials anode and cathode electrophoretic coating.

Electrophoresis process is divided into anode electrophoresis and cathode electrophoresis. If the coating particles are negatively charged, the workpiece is anode, and the coating particles are deposited into a film on the workpiece under the action of electric field force, which is called anodic electrophoresis; On the contrary, if the coating particles are positively charged and the workpiece is cathode, the coating particles are deposited on the workpiece into a film called cathode electrophoresis.

Anodic electrophoresis is characterized by: cheap raw materials (generally 50% cheaper than cathodic electrophoresis); Simple equipment, less investment (generally 30% cheaper than cathodic electrophoresis); Low technical requirements; The corrosion resistance of the coating is worse than that of cathodic electrophoresis (about 1/4 of the cathodic electrophoresis life).

The reasons for the high corrosion resistance of cathodic electrophoretic coating are as follows: the workpiece is cathode, no anodic dissolution occurs, and the workpiece surface and phosphating film are not damaged; Electrophoretic paint (usually nitrogenous resin) has a protective effect on metals, and the paint used is of high cost and quality.

| Input voltage | Three phase AC380V/440Vac±10%, 50-60HZ |

| Voltage regulation precision | ≤1% |

| Current regulation precision | ≤1% |

| Rated efficiency | ≥90% |

| Operation environment | -10-40℃ |

| Storage temperature | -20-50℃ |

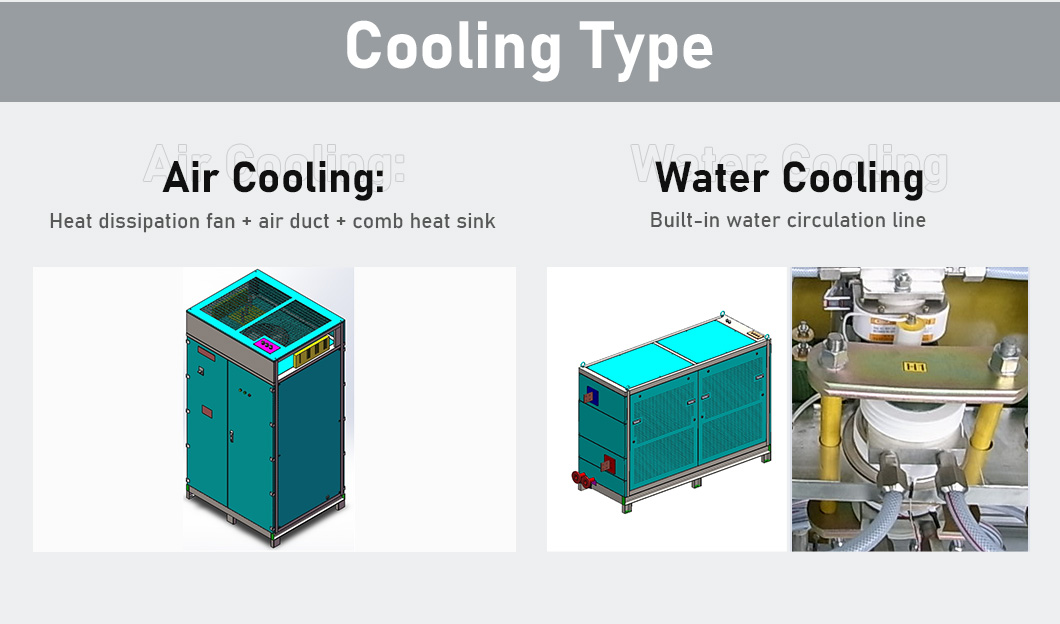

| Cooled mode | Air cooling, water cooled or oil cooled |

| Operation conditions | 24-hour operation under full load |

Hot Tags:0~250V 0~4KA Electrophoresis Power Supply KGSB Series,SCR Controlled Rectifier,Surface Treatment,Silicon controlled rectifier

If you have more questions, please leave us a message and we will contact you within 24 hours.