Products

Industries

Input parameters: Three phase AC380V±10%, 50~60HZ

Output parameters: DC 0~12V 0~5000A

Output mode: Common DC output

Cooling method: Water cooling

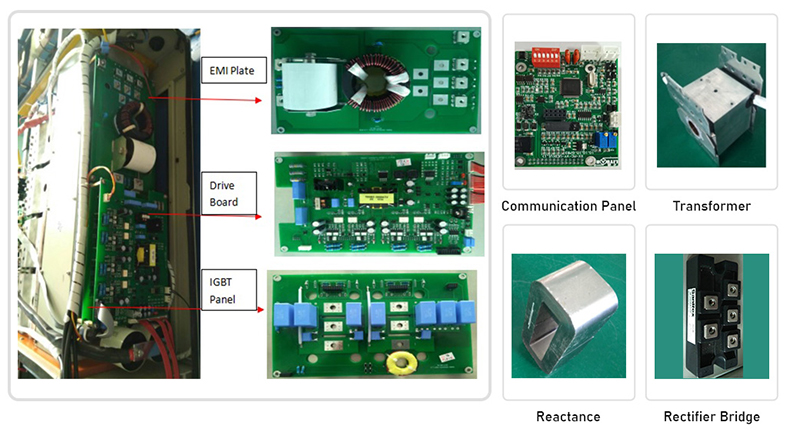

Power supply type: IGBT-based

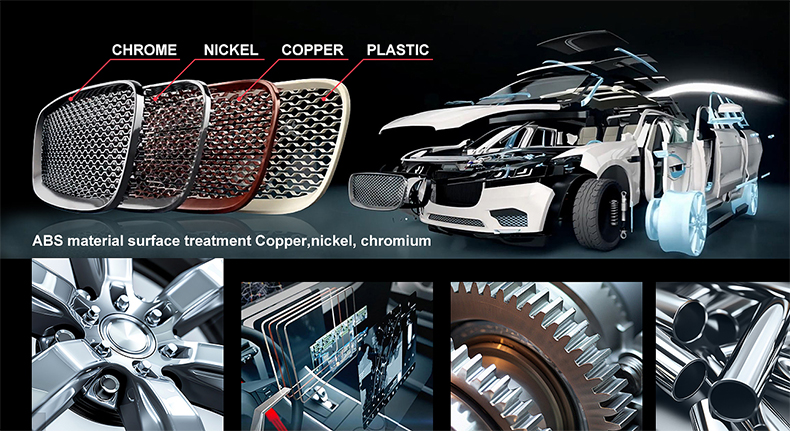

Application Industry: Surface treatment industry, such as chrome plating

AC input voltage is converted into a high-voltage DC output by the rectifier circuit and then filtered. This 0~12V 0~5000A IGBT-based rectifier for chrome plating is available at the factory price.

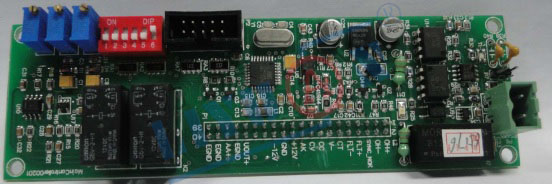

The “variable frequency conversion” stage inverts this high-voltage direct current into approximately 30kHz high-frequency alternating current. This high-frequency AC is then transformed into secondary voltage via a high-frequency transformer and filtered through a high-frequency rectifier circuit to produce the required output voltage. The plating rectifier power supply employs a control circuit to sample output voltage and current. These sampled signals undergo closed-loop feedback to generate pulse width modulation (PWM) signals, which regulate the inverter circuit and maintain stable output voltage/current – a critical requirement for precision electroplating applications.

Manufacturers widely use electroplating rectifier equipment for various surface treatment applications, including PCB electroplating, hard chrome coating, copper plating, nickel plating, zinc plating, gold plating, tin plating, and silver plating, among other metal finishing.

1)Field application diagram:

2)Industry application examples:

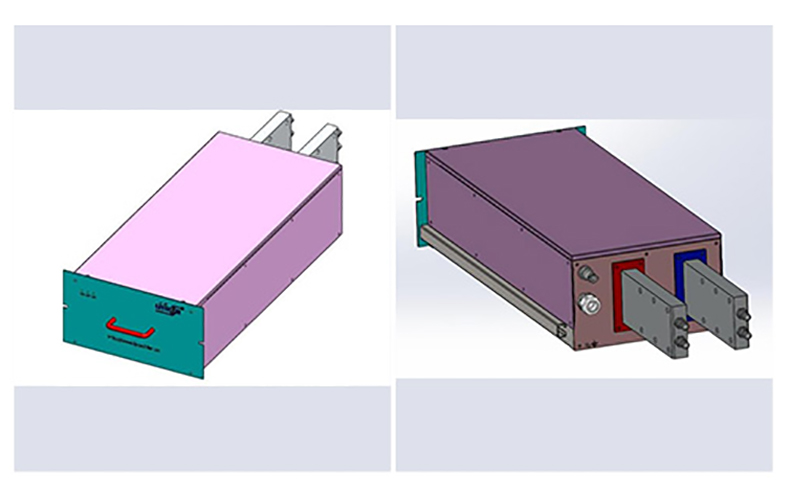

› Modular parallel connection

› Optional N+1 redundant backup

› Capable of online hot maintenance

› RS485 digital control function

› Low-voltage MOS tube rectification

› High power factor, high efficiency

› Reasonable structural design

› Effective sealed isolation

› No water joint design inside the unit

› Practical and effective multiple protection system

› Full soft switch technology

› High reliability

› Low noise, high protection level

Protection Against Corrosion

– Shields metal surfaces from rust and chemical damage (e.g., zinc plating on steel).

Increased Wear Resistance

– Hard coatings (e.g., chromium plating) reduce friction and extend part life.

Improved Appearance

– Adds shiny, decorative finishes (e.g., gold plating on jewelry, chrome on car parts).

Better Electrical Conductivity

– Used in electronics (e.g., copper plating on circuit boards).

Enhanced Solderability

– Improves bonding in electronic components (e.g., tin plating).

Repair of Worn Parts

– Restores dimensions and functionality (e.g., rebuilding engine components).

Special Industrial Uses

– Provides heat resistance (e.g., nickel plating in aerospace).

– Used in medical devices (e.g., biocompatible coatings).

› Copper Plating

Primarily applied to improve substrate adhesion for subsequent plating layers while enhancing corrosion resistance. Requires protective topcoats due to oxidation concerns—unprotected copper forms non-conductive patina over time.

› Nickel Plating

Serves as a functional base layer or decorative finish, offering excellent corrosion and wear resistance. Electroless nickel variants approach chrome-level durability. Note: Magnetic properties restrict usage in sensitive electronic components (e.g., RF connectors) where signal interference must be avoided.

› Gold Plating

Preferred for critical electrical contacts where stable impedance and optimal signal transmission are essential. Though highly reliable, material costs limit large-scale applications.

› Palladium-Nickel Plating

Superior wear resistance and signal stability vs. gold plating.

Combines palladium’s oxidation resistance with nickel’s structural integrity for high-cycle connectors.

› Tin-Lead Plating

Historically favored for solderability enhancement. Now largely discontinued due to RoHS regulations; modern replacements include pure matte or bright tin formulations.

› Silver Plating

Delivers maximum electrical conductivity and signal performance across high-frequency applications. Maintains functionality when oxidized but requires anti-tarnish treatments due to surface darkening. Premium cost reflects performance advantages.

› Selection Considerations

Specify plating type according to:

Required corrosion/wear resistance thresholds

Electrical performance parameters

Budgetary constraints

Environmental compliance requirements

Long-term maintenance considerations

› Cathode

The object to be plated (e.g., connector terminals or metal surfaces) where metal ions deposit into a solid coating.

› Anode

Soluble Anode: Made of the plating metal. Dissolves during electrolysis to replenish metal ions in the solution.

Insoluble Anode: Used for precious metals (e.g., white gold, iridium oxide). Does not dissolve but supplies electrons for reduction.

› Plating Solution

Contains ions of the target metal. Composition and concentration determine coating thickness, adhesion, and appearance.

› Plating Tank

Materials: Must resist corrosion and temperature fluctuations (e.g., polypropylene, titanium alloys).

Role: Stores solution and maintains stable plating conditions.

› Rectifier

Converts AC to DC power to drive electrolysis.

Adjust voltage/current to control deposition speed and coating thickness.

› Auxiliary Equipment

Filters: Remove impurities from the solution.

Heaters: Maintain solution temperature.

Stirrers: Ensure uniform mixing.

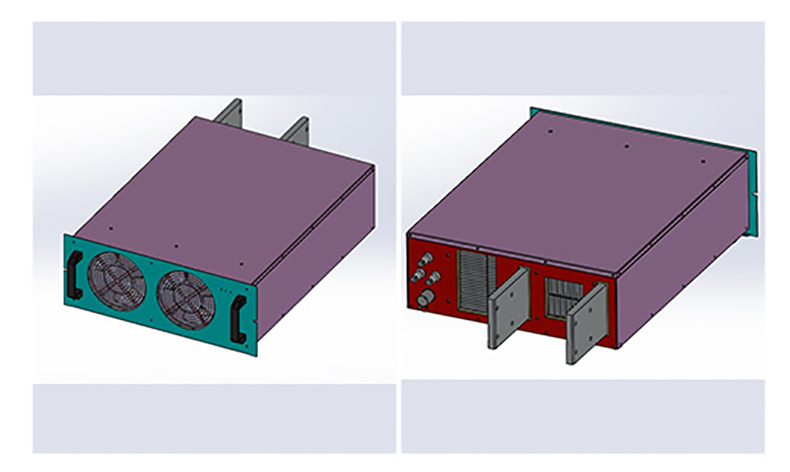

Air Cooling:Heat dissipation fan + air duct + comb heat sink

Water Cooling:Built-in water circulation line

| Characteristic Types | Parameter Items | Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBSB-5000A/12V | |

| Cooling mode | Water-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50~60HZ |

| Rated Input Power | 67.2KW | |

| Rated Input Current | AC 102A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~12V |

| Output Current | DC 0~5000A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 1A,0.01V | |

| Rated Output efficiency | ≥94% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤1500 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Other | Weight | About 30KG |

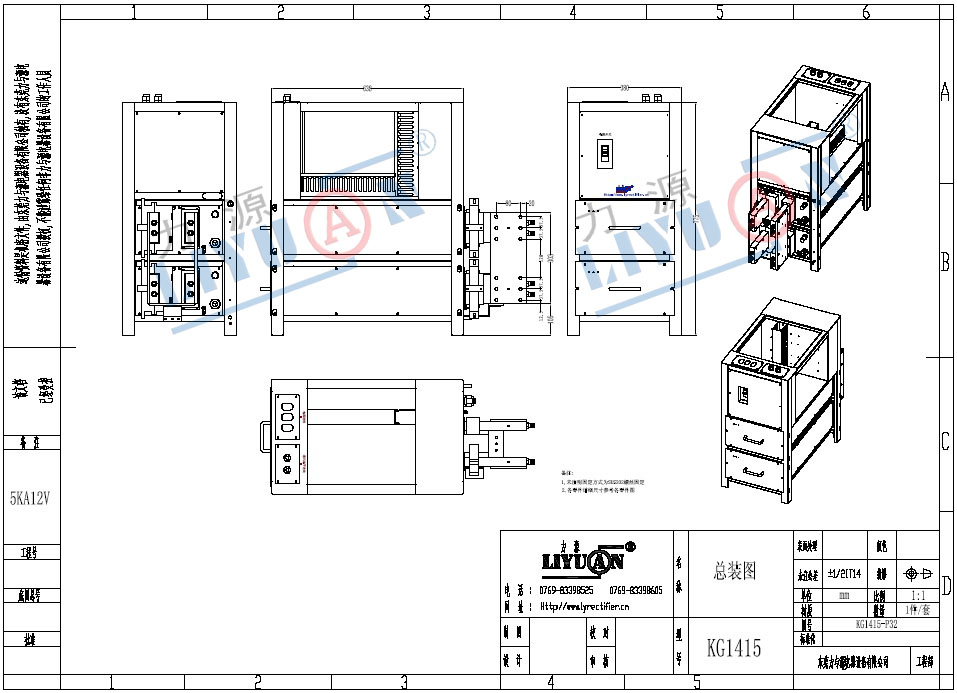

| External Dimension | Height*Width*Depth | H775mm×W380mm×D638mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit,

overheating and other abnormal self-protection function |

|

| Model | Input | Output | Dimension (mm)/L*W*H |

| TBSB-400A/12V | Three Phase AC380V±10% 50HZ | 12V/400A | 500*343*183 |

| TBSB-500A/12V | Three Phase AC380V±10% 50HZ | 12V/500A | 460*310*185 |

| TBSB-600A/12V | Three Phase AC380V±10% 50HZ | 12V/600A | 500*343*183 |

| TBSB-800A/5V | Three Phase AC380V±10% 50HZ | 5V/800A | 460*310*185 |

| TBSB-800A/6V | Three Phase AC380V±10% 50HZ | 6V/800A | 460*310*185 |

| TBSB-800A/12V | Three Phase AC380V±10% 50HZ | 12V/800A | 780*350*180 |

| TBSB-1000A/12V | Three Phase AC380V±10% 50HZ | 12V/1000A | 644*330*192 |

| TBSB-1000A/16V | Three Phase AC380V±10% 50HZ | 16V/1000A | 620*310*180 |

| TBSB-1000A/25V | Three Phase AC380V±10% 50HZ | 25V/1000A | 700*352*185 |

| TBSB-1000A/36V | Three Phase AC380V±10% 50HZ | 36V/1000A | 700*352*185 |

| TBSB-1000A/38V | Three Phase AC380V±10% 50HZ | 38V/1000A | 780*365*187 |

| TBSB-1200A/5V | Three Phase AC380V±10% 50HZ | 5V/1200A | 580*342*185 |

| TBSB-2000A/5V | Three Phase AC380V±10% 50HZ | 5V/2000A | 780*310*180 |

| TBSB-1800A/12V | Three Phase AC380V±10% 50HZ | 12V/1800A | 780*310*180 |

| TBSB-2500A/12V | Three Phase AC380V±10% 50HZ | 12V/2500A | 1024*340*180 |

| TBSB-3000A/12V | Three Phase AC380V±10% 50HZ | 12V/3000A | 700*352*185 |

| TBSB-3000A/15V | Three Phase AC380V±10% 50HZ | 15V/3000A | 824*340*180 |

| TBSB-4000A/10V | Three Phase AC380V±10% 60HZ | 10V/4000A | 700*362*185 |

| TBSB-4000A/15V | Three Phase AC380V±10% 50HZ | 15V/4000A | 824*340*180 |

| TBSB-5000A/7V | Three Phase AC380V±10% 50HZ | 7V/5000A | 700*362*185 |

| TBSB-5000A/15V | Three Phase AC380V±10% 50HZ | 15V/5000A | 824*340*180 |

| ※Can be customized according to requirements※ | |||

If you require surface plating rectifiers in other specifications, we can customize the design to match your exact needs. Please feel free to contact us for more details.

Looking for the factory price of a 0~12V 0~5000A IGBT-based rectifier for chrome plating? Liyuan Haina Rectifier, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Sweden, Netherlands, Italy, Spain, South Africa, Russia, Germany, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.

Hot Tags: 0~12V 0~5000A IGBT-based Rectifier for Chrome Plating, chrome plating rectifier, Metal Finishing, surface treatment industry, factory, price, China, manufacturers

If you have more questions, please leave us a message and we will contact you within 24 hours.