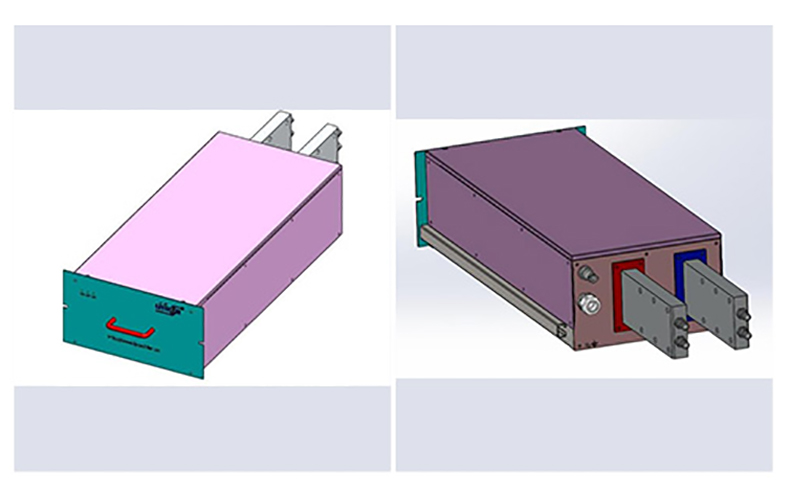

Rectifier for Copper Electrolysis Industry, the 8V 50A DC rectifier for copper electrowinning serves as the core power source, delivering precisely regulated DC supply for the cathode deposition process. This high-efficiency electrolysis power system ensures uniform copper ion deposition on cathode surfaces through stable current output, producing high-purity electrolytic copper. Operational data confirms the unit reduces energy consumption per ton of copper by 8-12% while elevating cathode copper grade above 99.99%. Its unique thermal management design maintains continuous operation in 45°C ambient conditions, particularly suitable for processing complex secondary copper materials.

The rectifier’s technical advantages directly translate to production process optimization. Through precise control of deposition parameters, it not only enhances primary copper quality but also significantly improves recovery rates of precious metals from anode slime. Operational reports from multiple smelters indicate approximately 15% increased recovery efficiency for scattered metals like selenium and tellurium, along with over 30% extended electrode service life. These improvements deliver substantial benefits across the entire electrorefining process.

Product Applications

Copper electrowinning rectifiers are primarily deployed in electrolytic refineries for cathode production, secondary copper processing plants, precious metal recovery operations, as well as electroplating, printed circuit board (PCB) manufacturing, and nanomaterial preparation. Their application extends to various hydrometallurgical processes including zinc electrowinning and nickel electrowinning, serving both new smelting projects and existing facility upgrades across the non-ferrous metals industry.

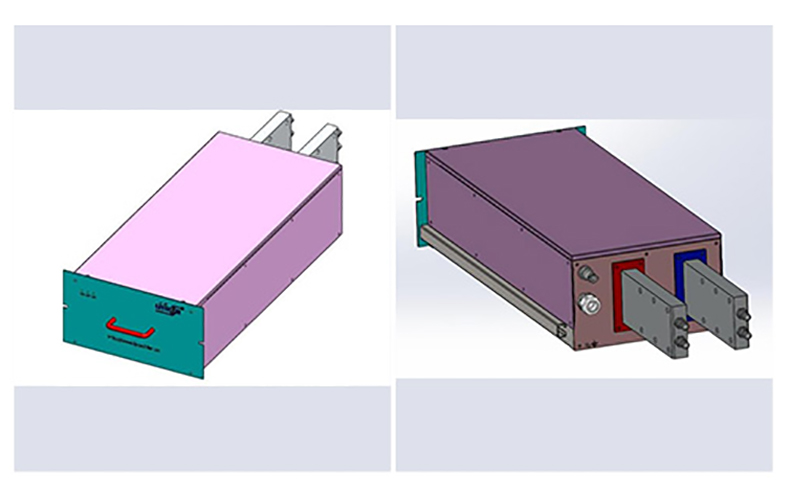

Field application diagram

Technology Advantages

› Dual-channel hot spare, scramble-free switching

› High-precision steady current control

› Critical loop redundancy design

› High reliability and stability

› User-friendly operation and easy maintenance

› Soft start and soft shutdown protection

› Automatic fault self-diagnosis

› Disturbance-free on/off loop switching

The Purpose of Copper Electrowinning

The primary purpose of copper electrowinning (EW), which produces electrowon copper, is to efficiently and economically extract high-purity metallic copper from a pregnant leach solution derived from low-grade ores or secondary materials, which are not amenable to conventional smelting methods. It is the crucial final step in the hydrometallurgical processing chain.

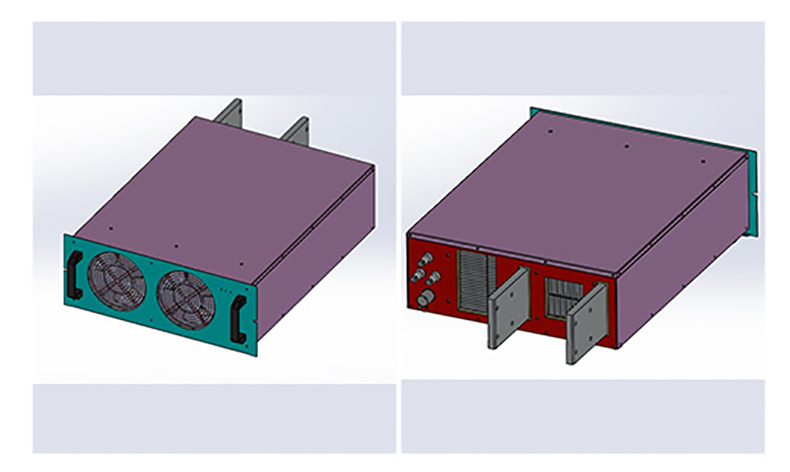

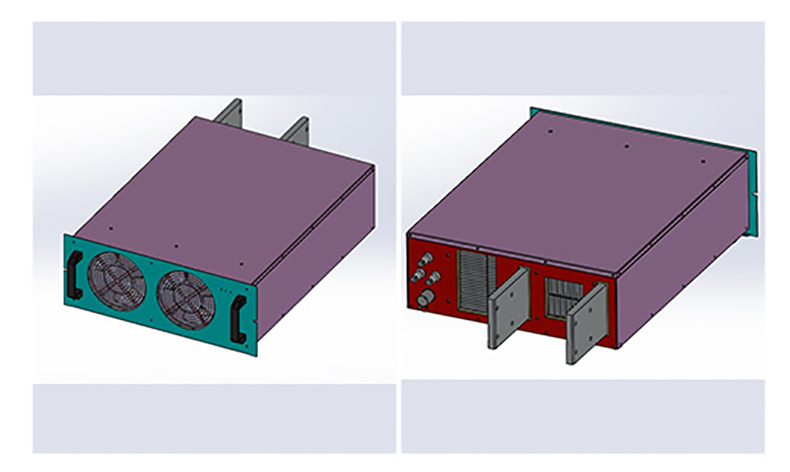

Cooling Type for Copper Electrowinning

Air Cooling:Heat dissipation fan + air duct + comb heat sink

Water Cooling:Built-in water circulation line