Products

Industries

Input parameters: Single phase AC220V±10%, 50HZ

Output parameters: DC 0~20V 0~30A

Output mode: Common DC output

Cooling method: Air cooling

Power supply type: IGBT-based High-frequency Power Supply

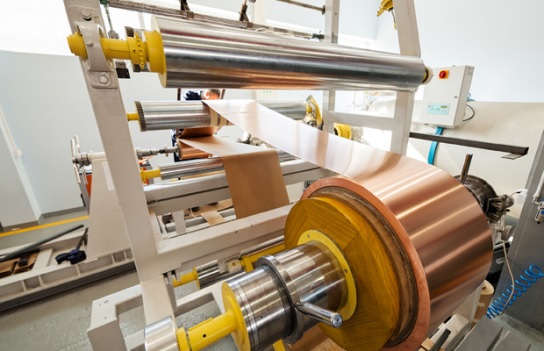

Application Industry: Electrolytic copper foil industry

Electrolytic copper foil refers to copper material as the main raw material, using electrolytic copper foil production. Dissolve copper material by copper sulfate solution, then in electrolytic equipment, copper sulfate solution by direct current electrodeposition and made the original foil, again carries on the coarsening, curing, heat resistant, corrosion resistant layer, prevent oxidation layer surface treatment, such as lithium electricity copper foil axial-flow compressor.in order main surface oxidation treatment, finally made after cutting, testing the finished product.

During electrolysis, cations in the electrolyte migrate to the cathode and electrons are reduced at the anode. The anion runs to the anode and loses electrons to be oxidized. Two electrodes were connected in copper sulfate solution and direct current was applied. At this point, copper and hydrogen will be found to precipitate from the plate connected to the cathode of the power supply. If it is a copper anode, copper dissolution and oxygen precipitation occur simultaneously.

Electrolytic copper foil, as a key functional basic raw material of electronic manufacturing industry, is mainly used in the production of lithium ion battery and printed circuit board (PCB). Among them, lithium copper foil has good electrical conductivity, good machining performance, soft texture, mature manufacturing technology, outstanding cost advantages and other characteristics, so it becomes the choice of lithium ion battery anode collector.

The module of the synchronous rectifier high-frequency switching power supply is installed in the parallel cabinet, and is connected with the cathode and anode bus of the foil generator through the output of the bus. Clean appearance, compact structure. High power conversion efficiency, reduce customer use cost. Power supply adopts N + 1 backup mode, which can realize thermal maintenance of the whole machine and ensure continuous production by customers.

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBFBZ-30A/20V | |

| Cooling mode | Air-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Single phase,AC220V±10% ,50HZ |

| Rated Input Power | 0.7 KVA | |

| Rated Input Current | AC 3.2A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~20V |

| Output Current | DC 0~30A | |

| Stabilized Current Precision | ≤1% | |

| Stabilized Voltage Precision | ≤1% | |

| Rated Output efficiency | ≥94% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤95% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 or RS232 |

| Other | Weight | About 32KG |

| External Dimension | Height*Width*Depth | H182mm×W527mm×D375mm |

| Protection Characteristics | Over voltage, over current, short circuit, lack of phase, over heat, water temperature, water pressure, water leakage and other protection functions. | |

| Application | Model | Output Parameters |

| 220V Single phase input | HIFB-500A4V | 4Vdc/500A |

| TBFBZ-600A4V | 4Vdc/600A | |

| HMFB-10A5V | 5Vdc/10A | |

| HMFB-20A5V | 5Vdc/20A | |

| TBFBZ-25A5V | 5Vdc/25A | |

| TBFBZ-400A5V | 5Vdc/400A | |

| HMFB-600A5V | 5Vdc/600A | |

| HMFB-800A5V | 5Vdc/800A | |

| HMFB-2A6V | 6Vdc/2A | |

| HMFB-3A6V | 6Vdc/3A | |

| HMFB-350A6V | 6Vdc/350A | |

| HMFB-5A6V | 6Vdc/5A | |

| HMFB-10A6V | 6Vdc/10A | |

| TBFB-50A6V | 6Vdc/50A | |

| HMFB-600A6V | 6Vdc/600A | |

| TBFBZ-1A9V | 9Vdc/1A | |

| TBFB-10A9V | 9Vdc/10A | |

| TBFBZ-20A9V | 9Vdc/20A |

Hot Tags: 0~20V 0~30A Rectifier for electrolytic copper foil,Electrolytic copper foil industry,copper foil electrolytic rectifier,Electrolytic copper foil,AC 220V Input,IGBT-based High-frequency Power Supply,copper electrowinning rectifier

If you have more questions, please leave us a message and we will contact you within 24 hours.