Products

Industries

Projects

The products are IGBT rectifiers, application in customer’s plating lines, the design adopt water-cooled, Each module has a hot-plug function, modules can be replaced without downtime, and not affecting normal production.

With touch screen control panel, red emergency button and all necessary protection.

Randomly we also included English maintenance manual and operation manual, operation and virtual video training document, definition diagram of all wires and connectors.

The rectifiers have been put into use, customer feedback that the performance is very stable, easy to operate, high efficient and energy saving greatly reduces production costs.

Hot Tags:Hard Chrome Plating industry,Peru ±15V 12000A Water Cooled IGBT Type Hard Chrome Plating Rectifier Project,Hard Chrome Plating Rectifier,igbt plating rectifier China,manufacturers,factory,sale,price

Project description:

Output current: 0~12KA

Output voltage: 0~15V

Efficiency: Over 90%

Project description:

Output current: 0~500A

Output voltage: 0~12V

Cooperative project: 12V 500A Zinc Plating Rectifier

IGBT type air cooled zinc plating rectifier with RS485 control mode. The efficiency of Liyuan IGBT rectifier is up to 94%, largely saving the production costs. Low ripple factor and high control accuracy.

Project description:

Input voltage: Three phase 380VAC, 60Hz

Output voltage: 0~10V

Output current: 0~8000A

The products are IGBT rectifiers, application in customer’s nickel plating lines, the design adopt water-cooled, 2 modules combined in parallel. Each module has a hot-plug function, modules can be replaced without downtime, and not affecting normal production.

With touch screen control panel, red emergency button and all necessary protection.

PLC & touch screen control is used for operation, which can implement automatic control with customer’s production. RS485 and 4~20MA, 0~10V analog signal control type.

Randomly we also included English maintenance manual and operation manual, operation and virtual video training document, definition diagram of all wires and connectors.

The rectifiers have been put into use, customer feedback that the performance is very stable, easy to operate, high efficient and energy saving greatly reduces production costs.

Project description:

Output current: 0~5000A

Output voltage: 0~10V

Cooling type: Air cooled

Control mode: RS485 local control

Project Description:

TBFB-250A/20V Output Voltage: 0~20VDC, Output Current: 0~250A

TBFB-500A/12V Output Voltage: 0~12VDC, Output Current: 0~500A

TBFB-1000A/15V Output Voltage: 0~15VDC, Output Current: 0~1000A

TBFB-2000A/15V Output Voltage: 0~15VDC, Output Current: 0~2000A

Project Description:

TBFB-600A15V

The customer is from Germany and is focused on electroplating and surface technology. It is one of the most reliable and high-quality suppliers of electrochemical or chemically applied metal coatings in Germany and Europe.

The TB series synchronous rectifier power supply independently developed by Liyuan is small in size, light in weight and more stable in output performance. The power conversion efficiency is up to 94%. The improvement of power efficiency greatly reduces the production cost of end users and improves the market competitiveness of customers’ products. At the same time, high performance power products also improve the surface treatment of product performance quality. The use of network centralized digital control technology greatly improves the control precision, reduces the cost of centralized control of power supply, and facilitates maintenance.

Project description:

TBFBZ-2500A12V Output current: 0~2500A; Output voltage: 0~12V

TBSB-10KA12V Output current: 0~10KA; Output voltage: 0~12V

TBFBZ-600A6V Output current: 0~600A; Output voltage: 0~6V

TBSB-5000A9V Output current: 0~5000A; Output voltage: 0~9V

Project Description:

KGFB-320A/400V Output Voltage: 0~400VDC, Output Current: 0~320A

The rectifier of this project is used for electrophoretic spraying, according to the customer’s usage environment and requirements, it is more suitable to adopt SCR design for high voltage, with the top air outlet to reduce the environmental dust into the rectifier and improve the power supply resistance. It has perfect protection functions such as phase failure, over-voltage, over-current, overheating, short circuit, etc. Meanwhile, it adopts unique sealing and sealing channel design to ensure that the equipment can work for a long time under the harsh environment with full load.

According to the electrophoresis process, the DC output is equipped with filter reactor and capacitor, so that the ripple coefficient index reaches the requirement of painting process, and the voltage of Tiven wave can make the paint film on the metal surface with dense structure, even thickness, smooth surface and strong adhesion.

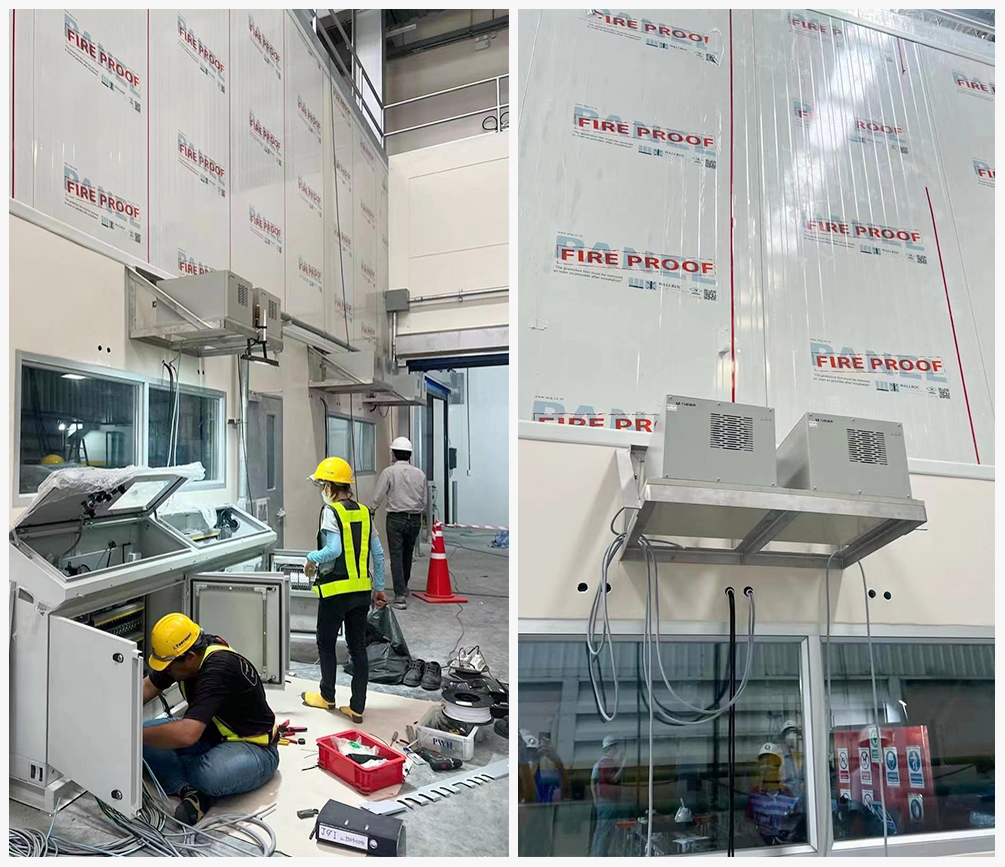

Customer country: Indonesia

The 22V/15KA anodizing aluminum rectifier project is cooperate with Indonesia customer. Customers are very recognized for the products and services, have been cooperating for many years.

The engineer was invited by the Indonesian customer to visit the factory for technical exchange guidance, on-site installation test of the anodizing power supply newly purchased by the customer, on-site operation guidance and training, and maintenance of the previously purchased rectifiers.

Project description:

TBSA-±30V/1200A Output current: 0~1200A; Output voltage: 0~±30V

Case introduction:

Four units of ±30V 1200A water treatment electrolysis rectifiers exported to Saudi Arabia, customer feedback rectifiers are on the stable operation and good performance, the energy efficient design not only saves costs, but also environment friendly. According to customer requirements, the rectifier adopt polarity reverse design, so the voltage can be switched in different processes. Above is the field application diagram sent by the customer, we are negotiating new project cooperation.

Liyuan self-developed wastewater treatment power supply can be widely used in various wastewater treatment processes, such as electrocoagulation of electroplating wastewater, electroadsorption, micro-electrolysis technology, and the removal of heavy metals electrolytic precipitation or floating, membrane electrolysis, electrodialysis and ion exchange method.

Based on the richness experiences and advanced technology, we have designed a rectifier as per customer’s specifications, Voltage and current can be adjusted independently, power supply can be displayed and controlled in the machine, or remote PLC display and control, at the same time with soft start ruanting function, soft start time and soft stop time can be set in the field cabinet. This rectifier largely improve the efficiency and save energy,better removal of all kinds of metal ions in the wastewater, so that the wastewater is purified.

Project description:

Output current: 0~445A Output voltage: 0~72V

According to customer’s requirements, they need a rectifier for water-electrolytic hydrogen making equipment. A common water electrolysis technique involves putting electrolytic water into a stack composed of catalytic cells and extracting hydrogen through a chemical reaction with electricity. Catalysts are connected to a power source to decompose water into oxygen and hydrogen gas and are normally made from expensive metals such as platinum or iridium.

The TB series synchronous rectifier power supply independently developed by Liyuan is more energy efficient stable in output performance. Made of the most energy-saving high-frequency MOSFET switching power supply, Liyuan third generation of new energy-saving MOSFET switching power supply, using synchronous rectifier MOS tube imported from the United States, Its voltage drop is only 0.IV, 0.6V lower than that of the ordinary second-generation HIGH-FREQUENCY switching power diode 0.7V, high current parallel structure and patented transformer design, efficiency can be up to 94% or more. This type of power supply has been used in many large projects at home and abroad for many years, energy-saving effect is obvious, and stable and reliable, It has been well received by many users.

Project Description:

TDSA-1200A/±30V

According to the requirements of water treatment process, the automatic reversing rectifier specially designed for customers can avoid the trouble of manual reversing and set the forward and reverse working time. Sealed design, to meet the environmental requirements of the use of the site, to improve the power resistance. Multi-function controller can be selected to match with the water treatment process.